What to Look for in a Reliable Wholesale DTF Transfer Supplier

Your supplier is either your silent partner—or the reason your production schedule just blew up.

In custom apparel, consistency isn’t just important—it’s the thread holding everything together. Deadlines are tight. Margins tighter. One weak link in your supply chain, and suddenly you’re staring down a pile of reprints, missed shipments, and an inbox full of client complaints.

That’s why choosing a DTF transfers wholesale supplier is more than just comparing price tags. It’s about trust. Precision. Staying ahead of the chaos instead of scrambling behind it. This piece breaks down the five traits that separate dependable DTF transfers wholesale providers from the ones quietly draining your margin and reputation.

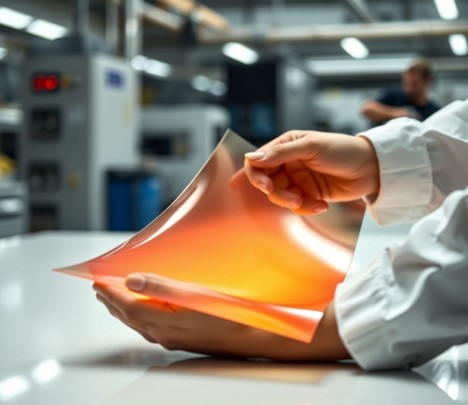

Consistent Print Quality

A single flawless batch doesn’t mean much if the next one flakes—literally.

Consistency is what counts. The kind that holds up across orders, sizes, and surfaces. When transfers behave unpredictably—peeling differently, colors shifting, prints cracking—you don’t just lose time. You lose trust.

And here’s the thing: the damage rarely shows up in one place. It spreads—rework, delays, unhappy customers. Rinse, repeat.

Watch for:

- Film and ink variations across batches

- Poor heat press compatibility (hot peel/cold peel confusion isn’t just annoying—it’s costly)

- Finishes that change under different press conditions

What you want is boring. Predictable. Transfers that behave the same way every time, so you can get on with running your business.

Real talk: flashy vibrancy is worthless if it can’t survive a wash.

[ILLUSTRATIVE EXAMPLE] A regional print shop started noticing uneven adhesion—some prints stuck, others lifted at the edges. Same settings, same press. It came down to batch inconsistency. After months of band-aid fixes, they switched to a supplier with tighter material control and eliminated the guesswork. Since then, they’ve relied exclusively on DTF transfers wholesale partners with strong quality benchmarks. [END EXAMPLE]

Reliable Turnaround Times

Fast is great. Reliable is better.

It’s not the flashy “48-hour” promise that matters—it’s whether those 48 hours are real. Missed deadlines hurt worse than slower but dependable timelines.

You’re not just ordering prints. You’re scheduling labor, organizing deliveries, and making promises to your customers. If your supplier can’t hit their own deadlines, you can’t hit yours. And clients don’t care why.

When evaluating turnaround reliability, consider:

- Average fulfillment time and delivery window consistency

- Buffer planning during peak periods

- How they communicate disruptions or changes

If a supplier ghosts you when things go sideways—or only talks when they’re on schedule—it’s a red flag. Reliable partners tell you the truth, even when it’s inconvenient.

[ILLUSTRATIVE EXAMPLE] An apparel startup aimed to launch a back-to-school line with tight drop dates. Their supplier offered 2-day printing but silently slipped to 6. Product drops got delayed, marketing budgets burned, and customers bailed. A future vendor with a steadier 5-day turnaround helped rebuild launch confidence using scalable DTF transfers wholesale production systems. [END EXAMPLE]

Transparent Communication & Support

Silence is not a strategy.

Especially not when you’re juggling multiple orders, prepping product shoots, or managing client expectations. Whether it’s file issues, rush requests, or unexpected downtime—communication can mean the difference between adjusting and unraveling.

Here’s what good communication looks like:

- Email replies in hours, not days

- A real person (or consistent contact) handling your account

- Status updates without being chased

Some suppliers disappear once you hit “submit.” That’s fine—until something goes wrong. Responsive partners build systems around clarity. They don’t leave you guessing.

[ILLUSTRATIVE EXAMPLE] A custom merch team caught a layout issue just before production. They flagged it. Their supplier replied within 20 minutes, corrected the gang sheet, and still shipped that day. That save? It preserved a brand client relationship they’d spent years building. [END EXAMPLE]

Scalability & Capacity Alignment

Today’s order isn’t the problem. It’s next month’s.

You might be cruising along with manageable volume now. But when a campaign takes off—or a retailer places a larger order—you need to know your supplier won’t buckle.

Key things to probe:

- Can they scale without sacrificing consistency?

- Do they have backup equipment? Cross-trained staff? Overflow processes?

- What’s their historical performance under pressure?

Scalability isn’t just about printing more. It’s about flexing without breaking—especially during seasonal surges or promotional spikes.

[ILLUSTRATIVE EXAMPLE] A fashion-forward streetwear brand doubled volume ahead of holiday season. Their legacy supplier missed delivery windows three weeks in a row. They pivoted to a vendor with dual-shift production and clearly defined surge protocols. Orders went out. Deadlines held. Their new provider even offered integration support for DTF gang sheet automation. [END EXAMPLE]

Reputation, Guarantees, and Terms

Reputation isn’t just what people say—it’s what companies commit to.

Anyone can show off five-star reviews. What you want are suppliers who put their guarantees in writing. Who show you their processes. Who offer transparency, not just promises.

Pay close attention to:

- Service level guarantees: delivery times, error rates, and resolution processes

- Refund and reprint policies that are documented, not just verbal

- Whether they’ll connect you with clients running similar volume

Solid suppliers aren’t afraid of scrutiny. In fact, they usually welcome it.

[ILLUSTRATIVE EXAMPLE] One vendor didn’t just talk up quality—they backed it with a written 2% reject rate cap and 48-hour reprint commitment. That kind of confidence, in writing, gave a mid-sized operation the clarity to double their order size without second-guessing. A DTF transfers wholesale provider willing to offer performance-backed terms is more than a vendor—they’re a risk mitigator. [END EXAMPLE]

Conclusion

Price matters. But predictability? That’s priceless.

When your DTF transfer supplier operates like a real partner—not a black box—you build something rare: stability. That shows up in your margins, your fulfillment rates, and your sleep.

Key Takeaways:

- A pretty print doesn’t mean much if it fails under pressure

- Scalable partners plan for growth—you don’t have to hope

- Guarantees separate vendors from true supply partners

Next Steps:

- Build a supplier scorecard with metrics that reflect your top pain points

- Compare current vendor performance to real-world fulfillment benchmarks

- Prioritize transparency and responsiveness in future partnerships

Frequently Asked Questions (FAQs)

Q: What is a realistic turnaround time to expect from a wholesale DTF supplier?

A: Typically, 3–5 business days. What matters more than speed is predictability. Look for consistency, not just marketing promises.

Q: How do I validate a supplier’s scalability without committing?

Ask for client references handling higher volumes. Request data—daily production limits, peak load history, and contingency planning.

Q: What supplier performance metrics should I track long-term?

A: Focus on:

- On-time delivery percentage

- Reject rate (keep it under 3%)

- Communication responsiveness

- Consistency across print runs

Frequently Unasked Questions (FUQs)

Q: How does poor DTF supplier performance affect downstream departments?

A: Missed shipments don’t just hurt fulfillment—they drain sales, stress support, and can cost you loyal customers. One delay can echo across the org.

Q: What hidden costs arise from unreliable vendors?

A: Beyond reprints and rush shipping? Think overtime payroll, wasted inventory, and even lost client contracts. It adds up fast.

Q: Why is supplier documentation (SOPs, guarantees) a competitive advantage?

Clear docs create clarity under pressure. They reduce room for confusion, speed up onboarding, and show you’re working with a supplier that takes process seriously.